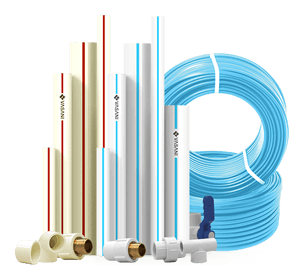

uPVC Pressure Pipes & Fittings

Product Brief

- HSN code : Pipes- 39172390 & Fittings – 39174000

- Material: Unplasticized Polyvinyl Chloride (uPVC)

- Pressure Rating: 2.5, 4, 6, 8,10,12.5 kgf / cm2.

- Size: 20 mm to 400 mm dia pipe available.

- Standard: IS : 4985 : 2000

- Colour: Light Grey

Form Supplied: Balled ended and Elastomeric PVC Pressure Pipes with Sealing Rings (RRJ) pipe in 6mtr. length.

uPVC Pressure Fittings

uPVC Pressure Moulded Fittings

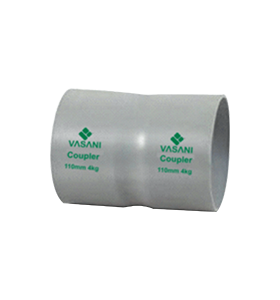

Coupler

More Details

Elbow

More Details

End Cap Plain

More Details

End Cap Threaded

More Details

F.T.A

More Details

M.T.A

More Details

Reducer

More Details

Reducer Tee

More Details

Service Saddle Hdpe

More Details

Tee

More Details

Elbow

More Details

Tee

More DetailsuPVC Pressure Fabricated Fittings

Advantages

Eco-Friendly

Low cost and Economical

Easy to Transport and Install

Non- Corrosive, Does not rust

Highly Flexible Can Take Heavy load

Non resistant to Chemicals & Electrical

Non Effective of Sunlight [ Weather Resistant ]

Suitable for over Ground, Underground & Under Water Usage

Non Effective to Rodents

Low Friction loss Which will Save Power Consumption

Technical Details

Jointing

For Ringfit Pipes :

Cleaning

The surface dirt, grease or moisture must be removed with a clean dry cloth.

Rubber Ring fitment

Take rubber ring & clean for surface dirt of any & insert in pipe groove by hand.

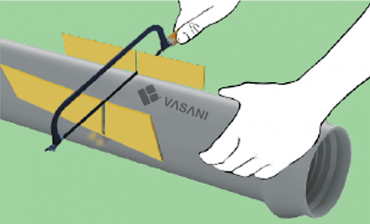

Cutting

The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage.

Chamfering and cleaning

The surface dirt, grease or moisture must be removed with a clean dry cloth. A 10° – 15° chamfer must be made at the end of the pipe.

Lubricant application

Apply even layer of lubricant on rubber ring and outer diameter of pipe prior to insertion.

Assembly

Push the pipe in integrated ring socket till end.

For Selfit Pipes & Fittings

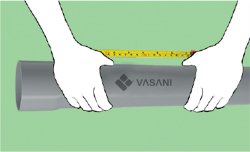

Measuring

Measure the required length of pipe and marking done.

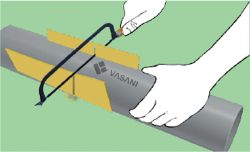

Cutting

The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage.

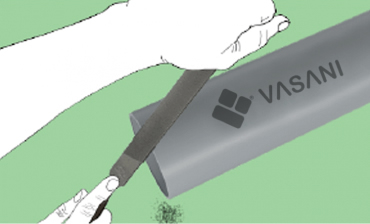

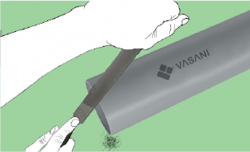

Deburring & Chamfering

All the burr must be removed from the inside and outside of the pipe with a knife, file or de-burring tool. A 10° – 15° chamfer must be made at the end of the pipe.

Cleaning

The surface dirt, grease or moisture must be removed with a clean dry cloth.

Check Dry Fit

Using light pressure, the pipe should be inserted one third to half the way into the socket. Note that pipes and fittings that are too tight or too loose should not be used.

Solvent Cement Application

An even layer of cement should be applied to the outer side of the pipe and a medium layer of the solvent cement to the inside of a fitting.

Assembly

Join the pipe and fitting socket till in contact with the socket bottom. Hold the pipe and fitting together until the pipe does not retract. The excess cement can be removed from the exterior surface of the pipe and fitting. A properly made joint will show a continuous bead of cement around the perimeter of the pipe and fitting.