uPVC Column Pipes & Fittings

Product Brief

- HSN Code : Pipes- 39172390 & Fittings – 39174000

- Material: Chlorinated Polyvinyl Chloride (CPVC)

- Pressure Rating: V4, MEDIUM DUTY, STANDARD DUTY, HEAVY DUTY, SUPER HEAVY

- Size: 1″- 4″

- Colour: White

- Length: 1.5 m & 3 m

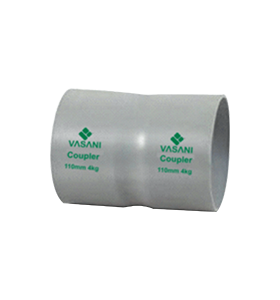

uPVC Casing Fittings

uPVC Casing Moulded Fittings

End Cap Threaded

More DetailsuPVC Casing Fabricated Fittings

Advantages

Strong, Durable and Maintenance free

World-Class Machining

Easy Handling, Transportation and Installation

Economical

Excellent Chemical Resistance

Non-Corrosive

Longevity of Life Cycle

Quality Water

Suitable for Cold & Hot Water upto 75°C

Suitable for Underground and Under Water Usage

Technical Details

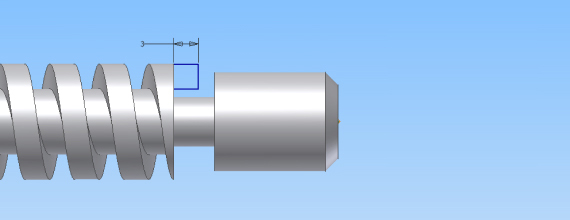

Square threads

Column pipes are provided with square threads for coupling joints. Due to their unique design, these pipes can withstand considerable shock, jerk load and pressure at full capacity when operational. Square threads ensure ease in joining with a high load holding capacity.

Specially designed “O” rubber ring

Made from EPDM rubber. It makes joints watertight and absorbs pump vibrations to ensure trouble-free operation, which extends the life of the motor and pumps Rubber Ring bearings.

Unique Locking System

A high torque resistance and double locking system are provided by using brass riveting, which promises extra safety in the long run.

Thick and Thin Construction

VASANI COLUMN PIPE are specially designed and manufactured to compensate for material removal during the threading operation by maintaining a thick section at the threaded end of the pipe. For the remaining pipe, a thin size is maintained. This manufacturing process promises additional strength at the threaded end.

Important Tips For Installation

- Pump delivery pressure should be less than the selected hydrostatic allowable pressure of column pipes.

- Bore-well drilling should be straight down without bending.

- During the dry run of the pump, the heat generated may damage the column pipe. In such a case, the initial 3 meter steel pipe must be connected directly to the pump for proper heat dissipation, before it reaches the column pipe.

- The diameter of the tube well shall be at least 2” to 2.5” more than the diameter of the pump.

- Always mount the split clamp on the pipe below the coupler at the top.

- If the pump does not have open discharge at the well head, another non return valve should be installed at the well head between top connector and system to be connected.

- Do not use pipes with damaged/scratched ends as such a joint may leak or fail.

- Check pipe threads are not damaged and clean it with normal water to avoid forceful jointing.

- Don’t use any chemical for cleaning the pipe thread.

- Ensure that rubber gaskets supplied with the pipe are properly placed in the groove on the male threads of pipe.

- Use plain water or soapy water for thread cleaning.

- Do not apply grease, oil or any other lubricant on the threads.

- Joint one pipe after the other. Tighten pipes by strap wrench so that 50% of the rubber-sealing ring on male thread end gets into the seat of coupler female threads.

- Do not over tighten the pipes as it may result in crushing of rubber seals leading to leakage/pipe crack.

- Do not use a pipe/chain wrench to tighten the joints.

- Don’t hammer the pipes during assembly.