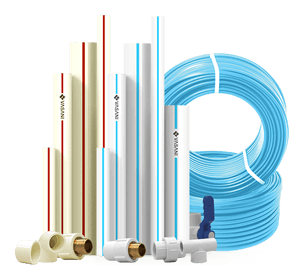

uPVC Casing Pipes & Fittings

Product Brief

- HSN Code : Pipes- 39172390 & Fittings – 39174000

- Material: Unplastisized Polyvinyl Chloride (uPVC).

- Pressure Rating:

- Shallow Casing (CS) pipe

- Medium Casing (CM) pipe

- DeepWell Casing (CD) pipe

- Tensile Strength 50 ± 5 N/mm

- SDR type Casing pipe is available in Size 4″ to 16″

- Colour: Deep Blue

- Form Supplied: CS – CM – CD pipe in 3mtr length with male- female thread socket

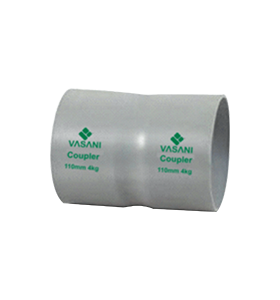

uPVC Casing Fittings

uPVC Casing Moulded Fittings

End Cap Threaded

More DetailsuPVC Casing Fabricated Fittings

Advantages

Strong, Durable and Maintenance free

Convenient Joining Have High Precision Trapezoidal Threads Which Ensure Easy Joining

Better Flow characteristics

Low Frictional Loss

Chemical & Bacterial Resistance

Eco-Friendly & Light weight

Low cost and economical

Easy to Transport and Install

Non- Corrosive, Does not rust

Suitable for Underground and Under Water Usage

Technical Details

Following factors may result in pipe deformation and bursting. Bore mechanics should take care while installation:

- Hydraulic pressure difference created by inside water and outside while drilling mud.

- Hydraulic pressure and heat created during bentonite/cement grouting.

- Stress formation due to types of rocks, clay and shale present outside the pipe.

- Development of sudden internal vacuum inside the pipe.

- Lateral compression and brittle failure after external impact of the hard bedrock.

CASING PIPE INSTALLATION GUIDELINES

- Drill the bore of the required size and depth in the ground. Care should be taken that it is vertical, without any bends.

- To obtain better results, ensure that the reamed borehole is at least 15 to 25 cm more than the outside diameter of the casing pipe.

- In bore wells with loose boulders, casing pipes are recommended for the entire depth.

- Use slotted pipes manufactured by Vasani. We do not recommend slotting to be done by any other company.

- Don’t use vertical slotted pipes in a bore well as they may not have enough strength and are not recommended by IS 12818 standard.

- Check to ensure that pipe threads are not damaged. Clean it with normal water to avoid forceful jointing. Don’t use any chemicals for cleaning pipe threads.

- Ensure that rubber gaskets are properly placed in the groove on the male threads of the pipe.