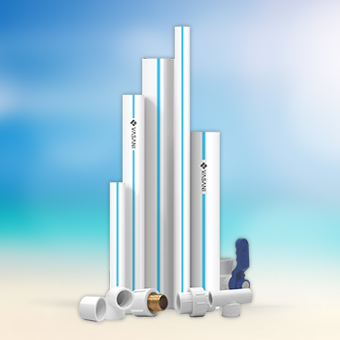

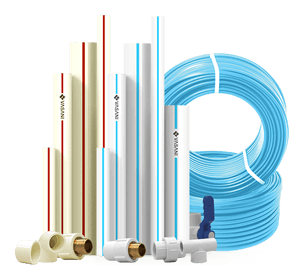

uPVC Plumbing Pipes & Fittings

Product Brief

- HSN Code : Pipes- 39172390 & Fittings – 39174000

- Material: Unplastisized Polyvinyl Chloride (uPVC).

- Pressure Rating: Schedule 40 & 80

- Size: 1/2″ to 4″

- Standard: ASTM D-1785

- Colour: White

Form Supplied: uPVC Plumbing pipe with 3mtr to 6mtr length.

uPVC Plumbing Fittings

Ball Valve

More Details

Bend Fabricated 90 Sch 40

More Details

Brass Elbow

More Details

Brass F.T.A.

More Details

Brass M.T.A.

More Details

Brass Tee

More Details

Coupler Socket

More Details

Elbow 45

More Details

Elbow 90

More Details

Elbow Threaded 90

More Details

End Cap

More Details

F.T.A

More Details

M.T.A

More Details

Reducer Bush

More Details

Reducer Elbow

More Details

Reducer Socket

More Details

Reducer Tee

More Details

Tank Connector

More Details

Tank Nipple

More Details

Tee

More Details

Union

More DetailsAdvantages

Strong, Durable and Maintenance free

Completely non-toxic Suitable for Portable Water Application and free from odor and taste

Easy solvent Weld Jointing With Proven Track Record

Fire Resistance

Eco-Friendly, Light weight and Cost Effective

Low Friction Loss and Resistance to Scaling

Easy to Transport and Install

Non- Corrosive, Does not rust

Technical Details

Jointing

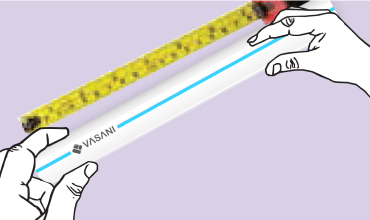

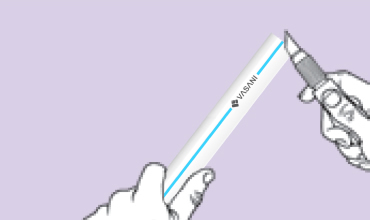

Measuring

Measure the required length of pipe and marking done.

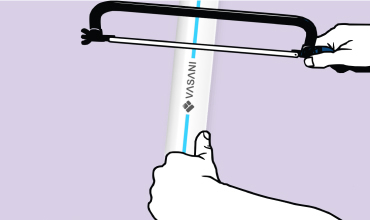

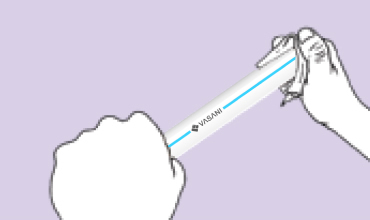

Cutting

The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage.

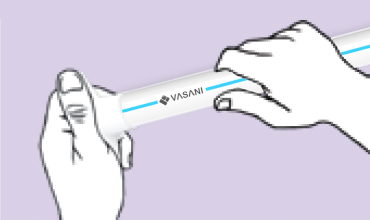

Deburring & Chamfering

All the burr must be removed from the inside and outside of the pipe with a knife, file or de-burring tool. A 10° – 15° chamfer must be made at the end of the pipe.

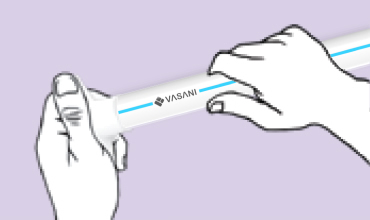

Cleaning

The surface dirt, grease or moisture must be removed with a clean dry cloth.

Check Dry Fit

Using light pressure, the pipe should be inserted one third to half the way into the socket. Note that pipes and fittings that are too tight or too loose should not be used.

Solvent Cement Application

An even layer of cement should be applied to the outer side of the pipe and a medium layer of the plumbing solvent cement to the inside of a fitting.

Assembly

Join the pipe and fitting socket till in contact with the socket bottom. Hold the pipe and fitting together until the pipe does not retract. The excess cement can be removed from the exterior surface of the pipe and fitting. A properly made joint will show a continuous bead of cement around the perimeter of the pipe and fitting.

Additional Information

DO’S

• Use pipes, fittings and solvent cements manufactured by Vasani Polymers Industries for best results.

• Installation should be completed as per instructions and recommended safe practices must be followed.

• Clean the pipe and fittings with a clean dry cloth to remove any dirt.

• Keep pipe and fittings in the original packaging until needed.

• In case any crack is found in the pipe, cut a minimum of 25mm length beyond the edge of the crack.

DON’TS

• Do not use metal hooks or nails to support/hold or put pressure on the pipes.

• Do not use straps and hangers with rough or sharp edges. Do not tighten the straps over the pipes.

• Never expose the pipe to open flame while trying to bend it.

• Do not drop pipes on edges from heights. Do not drop heavy objects on pipes or walk on pipes.

• Do not use air or gases for pressure testing.